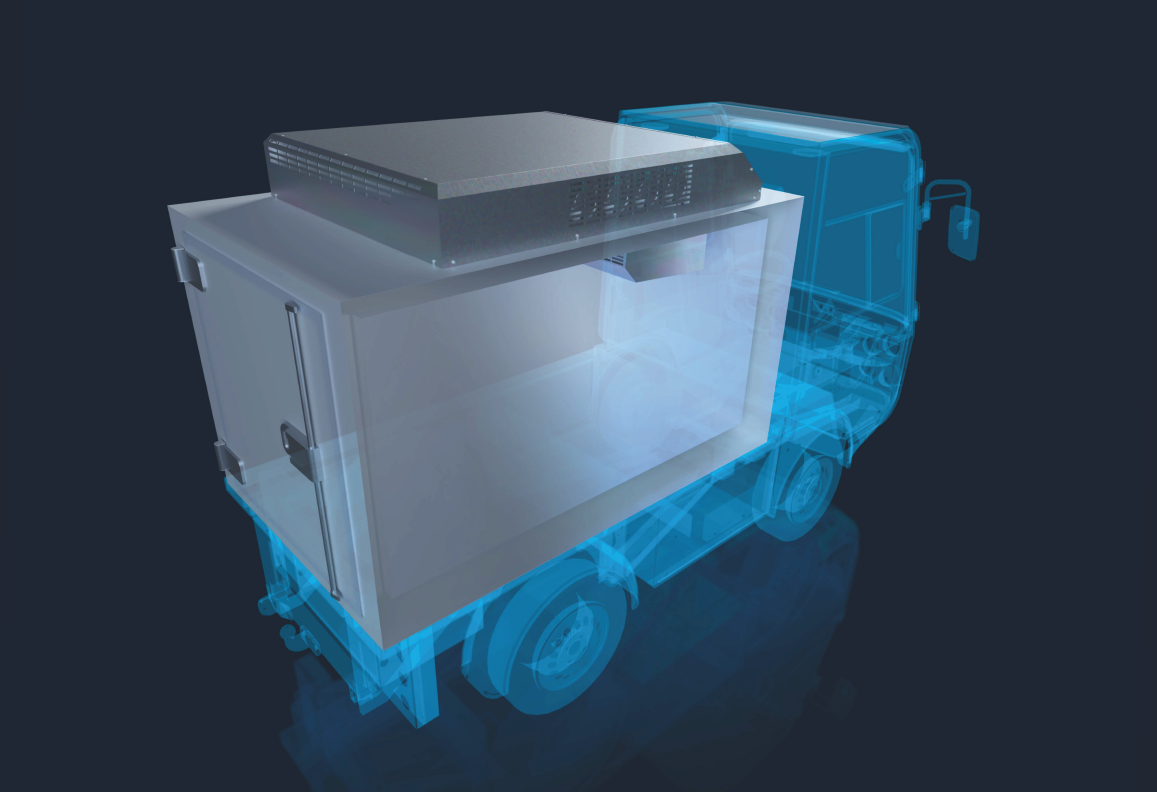

Coldway Technologies conçoit, teste et fabrique des groupes réfrigérants fonctionnant avec un système à sorption breveté et destinés à être assemblés sur des caisses isothermes pour le transport de produits thermosensibles dans les marchés de la Santé ou de l’Alimentaire.

Le système permet de produire une température de grande précision, en conformité avec toutes les exigences règlementaires en matière de nuisance sonores et de pollution atmosphérique, il offre une maintenance et des coûts opérationnels réduits, ce qui fait de lui, le seul système de réfrigération nomade parfaitement écologique.

Coldway Technologies exposait au salon SOLUTRANS, salon international des solutions de transport routier et urbain, en Novembre dernier à Lyon et concourrait aux i-nnovation Awards 2021 dans la catégorie ‘Equipementiers’.

i-nnovation Awards : les trophées de l’innovation pour les entreprises de la filière de la logistique et du transport

Anciennement ‘Prix de l’innovation’, les i-nnovation Awards récompensent les dossiers les plus innovants dans plusieurs catégories :

Anciennement ‘Prix de l’innovation’, les i-nnovation Awards récompensent les dossiers les plus innovants dans plusieurs catégories :

En sus, le Digital Award récompense les éditeurs de logiciels, sociétés d’ingénierie électronique s’étant illustrés dans le domaine de l’informatique ou de la connectivité pour la filière logistique/transport.

Ces trophées des i-nnovation Awards récompensent les nouveautés apportant une amélioration substantielle et significative, ainsi qu’un bénéfice concret pour les professionnels des métiers du transport et de la logistique : transporteurs, chauffeurs, donneurs d'ordres ou clients finaux.

Sofrigam Group exposait un véhicule de service équipé d’un système autonome de réfrigération Coldway Technologies au salon Solutrans à Lyon, avec ses partenaires Koovea, Addax Motors et Delivery Academy.

Sélectionnée parmi 80 dossiers et en lice avec 20 autres candidats, Coldway Technologies concourrait dans la catégorie ‘Equipementiers’ avec des concurrents prestigieux comme Bosch, Carrier Transicold ou encore Thermo King.

C’est à l’occasion d’une prestigieuse soirée de remise des prix au Groupama Stadium de Lyon que le jury nous a décerné le trophée de Bronze. Une reconnaissance du marché de la livraison urbaine décarbonée.

« Cette récompense confirme le caractère innovant et disruptif de cette technologie et notre détermination à réinventer le transport frigorifique autonome du 21è siècle. Nous tenons particulièrement à remercier les personnes qui sont venues nous rencontrer sur le stand. Nous tenons également à remercier tous nos clients et partenaires pour leur confiance et leur soutien depuis de nombreuses années. », Gilles Labranque, Président du groupe Sofrigam.

--> Consultez l’article du magazine Froid News sur les lauréats des I-nnovation Awards

Stand SOFRIGAM GROUP au salon Solutrans 2021 à Lyon

Véhicule électrique équipé du système de froid embarqué Coldway Technologies

Présentation de la technologie Coldway au jury des i-nnovation Awards 2021

Du 16 au 20 Novembre, la réfrigération écologique de Coldway Technologies s’invite à Lyon au salon Solutrans, le carrefour mondial du véhicule industriel et urbain. La thématique de cette édition, « Des solutions durables et connectées pour une filière de transport responsable » fait écho à la démarche de Coldway Technologies : disrupter le transport frigorifique avec une solution alternative pour les livraisons urbaines sous chaîne du froid. Decryptage.

Logistique verte, livraisons zéro-émission, logistique écoresponsable, transport durable, tous ces termes en vogue convergent vers une idée commune : l’avenir de la logistique sera innovant et durable ou ne sera plus.

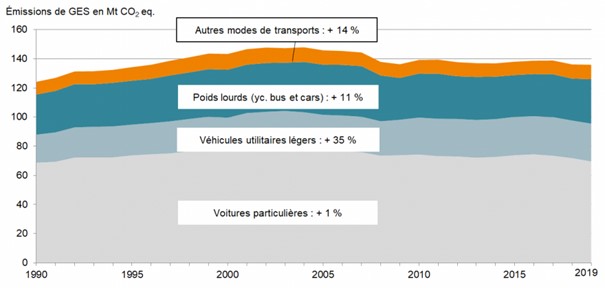

Entre 1990 et 2018, la quantité de marchandises transportées par route a augmenté de 30 % et le transport routier de marchandises a progressé de 56 %. Ce sont les véhicules utilitaires légers qui ont connu la plus forte progression de leurs émissions de GES (+35%) due à l’accroissement des livraisons en agglomération.

Et c’est d’autant plus vrai en ce qui concerne la logistique du dernier kilomètre sous chaîne du froid. Livrer des produits frais, en ville, aux moyens de véhicules frigorifiques thermiques sera très prochainement mission impossible.

A l’heure où le transport frigorifique doit être repensé pour s’adapter aux contraintes environnementales des agglomérations, il n’a jamais été autant convoité, boosté par la crise de Covid-19 avec les livraisons de produits alimentaires ou pharmaceutiques en ville.

> Les défis du transport frigorifique de demain

Ecologique, silencieux, agile, le froid embarqué autonome de Coldway Technologies apporte une réponse adaptée aux enjeux de la logistique urbaine du futur.

Coldway Technologies conçoit et fabrique des groupes réfrigérants fonctionnant avec un système à sorption breveté.

Ce système de réfrigération permet de produire une température de grande précision, en conformité avec les exigences réglementaires et impératifs environnementaux des agglomérations en matière de nuisance sonore et de pollution atmosphérique.

Destinés à être assemblés sur des conteneurs ou intégrés à des véhicules pour le transport de produits thermosensibles, les groupes frigorifiques de Coldway Technologies offrent une solution de livraison sous chaîne du froid :

Les groupes réfrigérants Coldway Technologies transforment les dispositifs sur lesquels ils sont installés en véritables enceintes réfrigérantes mobiles, avec un système de traçabilité intégré pour un suivi précis des températures.

Qu’il s’agisse de livrer en centre-ville, dans des ZFE, ou encore de nuit, le froid embarqué de Coldway Technologies apporte une solution innovante unique pour faciliter les livraisons urbaines du dernier kilomètre, sans nuisances et sans pollution.

Avec cette innovation majeure dans le secteur du froid industriel, Coldway Technologies amorce la transition énergétique du transport frigorifique vers une filière plus écologique, plus responsable et plus durable.

Des entreprises du transport alimentaire ou pharmaceutique, comme Gandon Transports et Saveurs & Vie, ont déjà adopté la solution Coldway Technologies pour leurs livraisons urbaines.

> Découvrez leurs témoignages dans ce numéro spécial de Froid News.

Le système de réfrigération de Coldway Technologies est à découvrir sur le stand Sofrigam Group au salon SOLUTRANS 2021, avec ses partenaires ADDAX, KOOVEA et DELIVERY ACADEMY.

SOLUTRANS | Le rendez-vous du véhicule industriel et urbain

16 - 20 novembre 2021 | Lyon Eurexpo, France

Stand SOFRIGAM GROUP Hall 1, allée A, emplacement n°42.

Et si les livraisons frigorifiques en ville s’effectuaient à vélo ? C’est la 20ème édition de la semaine européenne de la mobilité et du développement durable, dont le thème est « agir au quotidien ». L’occasion de revenir en chiffres sur les enjeux de la logistique urbaine du dernier kilomètre et de mettre en lumière le froid embarqué de Coldway Technologies. Combiner maîtrise de la chaîne du froid et livraison écologique zéro-émission, n’est-ce pas la clé pour agir au quotidien ?

Deux évènements majeurs d’ampleur européenne se tiennent en ce moment pour le climat :

La Semaine Européenne du Développement Durable (SEDD 2021) dont l’objectif est de sensibiliser le plus grand nombre au développement durable, de promouvoir des actions concrètes et d’engager à la mobilisation dans l’objectif d’atteindre les 17 objectifs de développement durable de l’Agenda 2030, adopté par l’ONU en 2015.

La Semaine Européenne du Développement Durable (SEDD 2021) dont l’objectif est de sensibiliser le plus grand nombre au développement durable, de promouvoir des actions concrètes et d’engager à la mobilisation dans l’objectif d’atteindre les 17 objectifs de développement durable de l’Agenda 2030, adopté par l’ONU en 2015.

La Semaine Européenne de la Mobilité (SEM 2021), qui vise à promouvoir des modes de déplacement respectueux de l’environnement. Le thème cette année : « En sécurité et en bonne santé avec les mobilités durables ».

Mobilité durable, décarbonisation, environnement, des thématiques ancrées dans l’ADN de Coldway Technologies, dont la vocation est d’offrir une technologie de froid embarqué autonome et zéro-émission pour des livraisons éco-responsables.

La logistique est l’un des secteurs les plus indispensables - nous l’avons constaté pendant la crise sanitaire de Covid-19 – mais aussi l’un des plus polluants.

C’est d’autant plus vrai pour le transport sous chaîne du froid, qui nécessite l’utilisation de véhicules frigorifiques encore très énergivores.

Quelques chiffres issus du site développement-durable.gouv.fr montrent qu'il reste du chemin à parcourir avant d'atteindre l’objectif de la neutralité carbone en 2050.

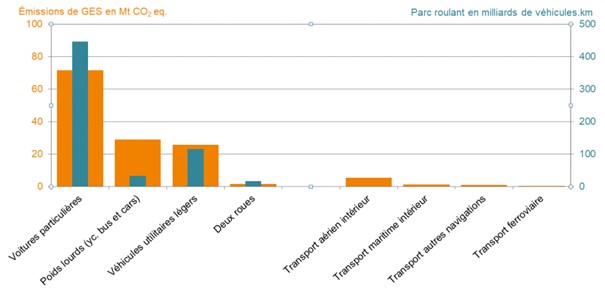

Répartition des émissions françaises de GES selon le mode de transport – France – 2018

Globalement, les kilomètres parcourus par des véhicules routiers ont progressé de 41 % entre 1990 et 2018.

Une progression qui s’explique par le développement sans commune mesure des livraisons en agglomération.

Évolution des émissions française de GES du secteur des transports par mode de transport en France de 1990 à 2019

La croissance du e-commerce, couplée à la démocratisation de la livraison à domicile, ont généré un accroissement considérable des flux de livraison en ville.

Sur l’année 2019, ce sont 50 millions de colis qui ont été livrés, soit une croissance de plus de 10% (chiffres de la FEVAD, 2020). L’essor de la livraison du dernier kilomètre est fulgurant.

La crise de Covid-19 a accentué le développement de la logistique du froid en ville, notamment avec le portage de repas à domicile, et la livraison de médicaments qui se démocratise.

Cette croissance des livraisons dans les agglomérations implique des problématiques d’accessibilité et de congestion qui s’accompagnent d’un lourd bilan écologique et de nuisances répétées pour les citadins :

Cette croissance des livraisons dans les agglomérations implique des problématiques d’accessibilité et de congestion qui s’accompagnent d’un lourd bilan écologique et de nuisances répétées pour les citadins :

Ces quelques chiffres clés montrent l’ampleur du problème du transport de marchandises dans les zones urbaines : à l’échelle nationale, la logistique du dernier kilomètre pèse environ 20% du trafic, occupe 30 % de la voirie, représente 50% du gazole consommé en ville et se trouve être à l’origine de 35 % des émissions de CO2, selon l’Agence de l’environnement et de la maîtrise de l’énergie (ADEME).

Dans un contexte marqué par la mobilité et le développement durable, le dernier kilomètre est un véritable défi dans la logistique urbaine et la livraison dans les centres-villes.

Chaque année en France, 100 millions de tonnes de produits sont distribuées par camions frigorifiques. Ce chiffre pourrait doubler d’ici 2025, notamment parce que le transport frigorifique occupe une place fondamentale dans l’industrie alimentaire et pharmaceutique.

En outre, la réglementation sur les fluides frigorigènes, les enjeux environnementaux et les coûts énergétiques du transport frigorifique conduisent les acteurs de la logistique du froid à se réinventer.

« Le premier défi dans le transport concerne le remplacement des fluides frigorigènes. Aujourd’hui certains sont encore à fort GWP [Global Warming Potential : potentiel de réchauffement global] », explique Gérald Cavalier, président de Cemafroid-Tecnea, dans le dossier spécial sur la logistique du froid de Voxlog.

La logistique réfrigérée du dernier kilomètre doit évoluer pour répondre :

Opérer des livraisons de produits frais en ville avec des moyens de transports alternatifs en conservant la même traçabilité que pour un véhicule thermique, c’est désormais possible avec le froid embarqué de Coldway Technologies.

Coldway Technologies conçoit des groupes réfrigérants autonomes, assemblés sur des conteneurs ou intégrés à des véhicules propres, pour livrer sur le dernier kilomètre avec des moyens de transport doux.

Vélos-cargos, scooters électriques, véhicules électriques, le froid autonome de Coldway Technologies s’adapte à tous les moyens de transport pour effectuer des livraisons en ville, de jour comme de nuit, sans pollution, sans nuisance sonore, dans le strict respect de la température des produits transportés.

Les groupes réfrigérants de Coldway Technologie sont complètement indépendants des batteries du véhicule. Ils fonctionnent avec un réfrigérant naturel, plébiscité par les autorités gouvernementales en remplacement des HFC.

Véritable alternative écologique aux véhicules frigorifiques, ils offrent une maitrise parfaite de la température pour un transport mono ou multi températures, avec un système de traçabilité intégré.

De nombreuses collectivités et entreprises ont adopté la technologie Coldway pour le transport de produits alimentaires ou pharmaceutiques.

En cette semaine du développement durable, quel meilleur moyen d’agir au quotidien que de choisir une solution de transport frigorifique alternative ?

Le SITL est un événement annuel majeur pour les acteurs du transport et de la logistique. Cette édition 2021 met l’innovation et la logistique verte à l’honneur. Une vitrine de choix pour les systèmes frigorifiques Coldway Technologies qui offrent une alternative écologique à la livraison urbaine du dernier kilomètre. Une solution de transport frigorifique à découvrir sur le stand Sofrigam Group du 13 au 15 septembre à Paris Porte de Versailles.

On estime que le froid utilise environ 20 % de l’électricité totale consommée au niveau mondial. Chaque année, rien qu’en France, ce sont 100 millions de tonnes de produits thermosensibles* qui sont livrés par véhicules réfrigérants.

Quant au transport de marchandises, il est le premier secteur émetteur de gaz à effets de serre en France, avec près de 30 % des émissions. Le dernier kilomètre est le maillon le plus coûteux et le plus polluant de la chaîne de livraison. Il représenterait entre 30 % et 40 % des coûts économiques du transport, mais aussi des émissions polluantes.

Pourtant, la crise de Covid-19 a révélé le rôle indispensable au quotidien de la logistique du froid dans des domaines industriels clés tels que la santé et l’alimentation. Une logistique en pleine croissance qui accentue les flux de livraison au cœur des villes, déjà engorgées et soumises à la pollution et aux nuisances visuelles et sonores.

Dès lors, comment accompagner le développement du transport frigorifique pour la livraison urbaine de manière écologique ?

Imaginiez-vous un jour pouvoir livrer en centre-ville des produits surgelés, frais ou chauds, sans risque, à toute heure du jour ou de la nuit, sans bruit et sans pollution ?

C’est ce que rend possible le système de réfrigération Coldway Technologies : une technologie de production de froid autonome, silencieuse et écologique, qui peut être adaptée sur tout type de contenant ou de véhicule (véhicule utilitaire, scooter, tricycle ou vélo).

Elle rend possible un autre modèle de livraison urbaine à température dirigée, utilisant des moyens de transport alternatifs pour une logistique sous chaîne du froid décarbonée.

« Coldway Technologies, c’est une avancée majeure dans la transition écologique et énergétique de la logistique et de la réfrigération grâce à des solutions de livraison en centre urbain silencieuses, décarbonées et 100% vertes. »

Ce système frigorifique apporte une solution innovante unique pour faciliter les livraisons du dernier kilomètre en centre-ville, sans nuisances et sans pollution.

Une solution de réfrigération autonome et éco-responsable déjà adoptée par les secteurs du transport alimentaire ou pharmaceutique, comme Gandon Transports et Saveurs & Vie dont vous pouvez découvrir les témoignages dans ce numéro spécial de Froid News.

Le système de réfrigération de Coldway Technologies est à découvrir sur le stand Sofrigam Group au salon SITL 2021.

SITL | 13 – 15 septembre 2021 | Paris Porte de Versailles

Stand Sofrigam Group K019, Hall 1.

* Etude Les Echos sur le marché de la logistique du froid, Novembre 2018.

S’il est une technologie de réfrigération qui a sa place dans un salon dédié au développement durable et aux technologies vertes de demain, c’est bien le système Coldway Technologies.

Innovant, écologique, durable, mobile, cette technologie de réfrigération autonome a tous les critères pour conquérir la ville de demain.

Exposé au salon Produrable le 7 et 8 septembre 2020 à Paris, le système Coldway Technologies est présenté par Gilles Labranque, son président, dans la vidéo ci-dessous :

SOFRIGAM GROUP et son entité Coldway Technologies sont très fiers d’annoncer le lancement du nouveau site Internet coldway.com ce jeudi 17 septembre. Toute l’expertise, l’innovation et la technologie de ce système de réfrigération autonome du 21e siècle y sont présentées. Le froid du futur est désormais une réalité, et il se veut résolument écologique et responsable.

Autonome, mobile, silencieux, durable, le système de réfrigération Coldway Inside est une technologie éco-responsable complètement décarbonée.

une alternative à la nouvelle réglementation régissant les fluides frigorigènes.

Les conteneurs isothermes équipés d'un système de production de froid basé sur la sorption solide-gaz offrent une solution pour le transport sous température contrôlée. Cette solution régulée et autonome combine les avantages de la solution statique (caisse isotherme) et de la solution dynamique (groupe frigorifique).

Découvrez cette publication sur le stockage thermochimique parue dans la RGF (Revue Générale du Froid), réalisée conjointement par les experts Sofrigam et Coldway Technologies, avec le laboratoire CNRS-PROMES.

Consulter la version en ligne sur le site Sofrigam

Article rédigé par :

Abbes KACIMI, Directeur Expertise Chaîne du froid, Sofrigam,

Francis KINDBEITER, Directeur R&D, Coldway Technologies,

Driss STITOU, Responsable Equipe de recherche TES au Laboratoire CNRS-PROMES.

Gilles Labranque, PDG de SOFRIGAM GROUP dont fait partie l'entreprise Coldway Technologies, était l'invité de BFM Business. La croissance du transport sous température dirigée et les problématiques environnementales poussent les acteurs du secteur à s'adapter et à innover. Coldway Technologies offre un système de production de froid autonome, écologique et silencieux qui facilite et sécurise la livraison urbaine sous température dirigée.

« Nous sommes les leaders mondiaux de la réfrigération par absorption, qui est le froid autonome du XXIe siècle », Gilles Labranque

Les leaders mondiaux de la réfrigération par absorption

Selon une étude du cabinet Temperature Survey, le marché du transport sous température dirigée est évalué à 10 milliards d’euros. Il devrait même augmenter de plus de 50 % d’ici 2025. C’est ainsi que de plus en plus d’entreprises de transport se dotent de véhicules réfrigérés, afin de s’adapter à ce marché en développement...

En 10 points le livret de l'Union nationale du transport frigorifique (UNTF) résume les règles à respecter pour limiter les remontées en

température des caisses pré-refroidies à -10°C.

Synthétiser sous forme didactique les 10 bonnes pratiques à promouvoir pour le chargement et le transport de

produits surgelés, c'est ainsi que se présente le petit dépliant conçu par l'UNTF. « La réalisation de ce livret constitue la dernière étape d'une démarche menée

en collaboration avec le Cemafroid. Elle s'est appuyée sur une étude réalisée par cet organisme, laquelle valide qu'une température de -10 'C suffit pour le pré-refroidissement d'une caisse vide destinée

au chargement de produits surgelés dės lors que neuf autres conditions sont remplies, indique Valérie Lasserre, deléguée générale de lUNTF. C'est donc sous forme de puzzle que nous avons mis en scène l'ensemble de ces paramètres ».

Une large diffusion

Les transporteurs sont appelés à télécharger le livret sur le site de l'organisation pour en assurer une très large diffusion autour d'eux en prévision de la prochaine période estivale. Si cet outil sedestine en premier lieu aux clients chargeurs, chaque maillon de la chaine du froid est appelé à la vigilance, conducteurs et des agents de quai compris. D'où le travail de promotion qui sera mené auprès des organisations professionnelles voisines, qui représentent les expéditeurs, distributeurs et entrepositaires.

Charger le plus rapdiement possible

Le point numéro 7 s'adresse ainsi aux industriels et entrepôts de stockage intermédiaire : il préconise le chargement de produits stabilisés et à une température de-18°C au minimum. Aux agents de quai est rappelée l'importance de réaliser le chargement le plus rapidement possible (point 5) pour éviter les remontées en température.

La nécessité d'utiliser un quai réfrigéré s'impose aux expéditeurs: « Il arrive que certains d'entre eux n'en disposent pas ou se contentent de quais partiellement réfrigérés tandis que les destinataires en sont généralement équipés », note Emmanuel Tanguy, animateur de la commission "process" de l'UNTF.

Capitaliser sur le froid résiduel

L'organisation entend également sensibiliser ses propres adhérents transporteurs et leurs préposés sur d'éventuelles mauvaises habitudes à éradiquer. Oublier d'arrêter le groupe frigorifique avant l'ouverture des portes du véhicule, par exemple.

« L'utilisation d'un thermomètre laser, trop imprécis, doit être réservée à la phase de première impression. Dès que se dessine un risque de non-conformité, il convient d'utiliser un thermomètre à sonde (et conforme à la norme 13 486 !), surtout pour vérifier au contact et à coeur des produits », insiste Valérie Lasserre. En parallèle, les transporteurs veilleront

à assurer une bonne température de l'air dans leur véhicule (point 7) et à utiliser une paroi amovible pour les chargements partiels (point 8). Le tout pour leur plus grand profit, assure Emmanuel Tanguy: « La présentation de la caisse vide peut maintenir la température, mais en aucun cas l'abaisser. Réduire le temps de remise à la bonne température en capitalisant sur le froid résiduel permet de réaliser des économies à la fois financières et énergétiques ».

Coldway Technologies est l'exemple parfait d'une transition réussie entre innovation universitaire et développement industriel. Après un démarrage en start-up et un rachat par le Groupe Sofrigam, la PME catalane ambitionne de devenir le N°1 du froid.

Denrées alimentaires, médicaments, vaccins, automobile, climatisation, le froid est aujourd'hui incontournable dans notre vie quotidienne et dans de nombreuses activités économiques. Il l'est tout autant dans les grands débats environnementaux, où il pose deux enjeux majeurs : disposer d'alternatives à l'utilisation des gaz frigorigènes fluorés et contribuer à réduire la consommation d'énergie.

Une innovation majeure

Créée en 2001 à Pia dans les Pyrénées-Orientales, près de Perpignan, Coldway Technologies est à l'origine une jeune pousse technologique française. Issue d'un transfert de technologie CNRS, elle développe et met sur le marché diverses applications à partir d'une innovation majeure fondée sur le stockage et l'utilisation de l'énergie dans la chaine du froid.

L'originalité de cette invention, brevetée au niveau international, réside dans un procédé autonome utilisant un réfrigérant

naturel, sans pollution sonore et sans consommables, offrant des économies de coûts opérationnels à ses utilisateurs.

Plus de 10 ans de recherches

A l'origine du procédé développé par Coldway, plus de 10 ans de recherche fondamentale engagée par l'Institut de science et génie des Matériaux et Procédé (IMP, aujourd'hui le laboratoire Promes), unité du CNRS, qui a permis de développer un procédé de production et de gestion autonome de froid à partir d'une réaction chimique solide-gaz. L'entreprise a rejoint fin 2018 le groupe Sofrigam, n°1 européen de l'emballage réfrigérant dédié à l'industrie pharmaceutique. Une reprise qui lui permet de se développer dans les meilleures conditions et d'avoir les moyens de ses ambitions. C'est une technique de fabrication de froid par sorbtion, autrement dit une réaction chimique à partir de l'amoniac en circuit fermé. C'est une solution vertueuse, écolo, autonome pendant 24 heures », renchérit Laurence Labranque, directrice de la PME, fille du fondateur.

Maîtriser la chaîne du froid

Les solutions qu'elle apporte à des secteurs industriels diversifiés, allant de l'univers médical à la restauration hors domicile en passant par la logistique et le transport, répondent toutes à l'exigence absolue sanitaire de maitrise de la chaine du froid, - suivi et traçabilité des températures, souplesse et fiabilité dans le transport de produits sensibles à températures constantes. Cette technologie est aujourd'hui la solution attendue par le marché pour répondre aux exigences règlementaires en matière de réduction d'émission de gaz à effet de serre.

Produire du froid & de la chaleur

Le procédé développé repose sur un principe simple : produire du froid et de la chaleur de manière immédiate, autonome et puissante à partir d'une réaction chimique élémentaire entre de l'ammoniac et des sels, contenus dans un réacteur et un évaporateur. Cette production de froid et de chaleur immédiate peut avoir une amplitude de -30°C à plus de 200°C. La production de chaleur et de froid peut ainsi se faire à tout moment et en tout lieu, sans aucun branchement nécessaire.

Cette production se fait sans aucun bruit et sans aucune vibration. Les éléments réactifs, - ammoniac, sels et graphite -,

sont parfaitement confinés dans un circuit hermétique scellé en usine, ne nécessitant aucun remplissage.

Une réutilisation à l'infini

Une fois l'ammoniac entièrement évaporé, la production de chaleur et de froid s'arrête et le système peut être rechargé avec un apport de chaleur extérieur (par énergie électrique, solaire, récupération de chaleur industrielle...) qui provoque la condensation de l'ammoniac. Régénéré, le système thermochimique stocke l'énergie et est à nouveau prêt à être utilisé. Le cycle est réversible à l'infini, comme le prouvent les tests réalisés par Coldway Technologies, au cours desquels plusieurs milliers de cycles de production et de recharge ont été effectués. Ce procédé est aujourd'hui reconnu par des opérateurs industriels de référence qui ont choisi d'enrichir leurs solutions avec cette technologie.

Toute une gamme de conteneurs

La maitrise de son procédé à sorption a permis à Coldway Technologies de développer toute une gamme industrielle de conteneurs isothermes, réfrigérés et autonomes, sans branchement électrique permettant le stockage et le transport de produits thermosensibles à température choisie, dans des plages horaires allant de 24 à 48 heures d'autonomie. L'innovation apporte aussi une réponse à des enjeux de transport de produits thermosensibles et de traçabilité des températures des produits transportés. Son département ingénierie travaille déjà à de nombreux projets d'applications imaginables, développées sur mesure pour répondre aux attentes et aux besoins des industricls, tel Olivo, le premier fabricant français de Rolls isothermes qui a choisi Coldway en 2019 pour équiper sa nouvelle génération de Rolls autonomes et écoresponsables

Le groupe Coldway Technologies A420 Intégré à une enceinte isotherme C1300L répond à de très nombreuses applications en calsse rapportée. Pour le transport dans un vehicule sec, Coldway Technologies préconise, en particulier, ce groupe A420 intégré à une caisse isotherme embarquée C2000L. Les groupes sont maintenant positionnés en-dessous de l'enceinte sur les gros volumes pour une meilleure stabilité dans le véhicule, et aussi pour une meilleure accessibilité au module de commande.

Citons entre autres clients, Saveurs et Vie pour le portage de repas sur Ligier Pulse 3 et Pulse 4 dans Paris, ou encore Gandon Transports qui exploite la solution Coldway Technologies depuis 2017 et compte une douzaine de rolls 1100L OL dans 9 succursales de son reseau pharma en -2°C/-8°C et +15°C/+25°C.

Avec Coldway Technologies. Sofrigam Group peut désormais nourrir de grandes ambitions sur la logistique urbaine éco-responsable, de jour comme de nuit.

L’entreprise Coldway Technologies présente sa technologie disruptive de réfrigération au salon Move à Londres les 11 et 12 février. 100% autonome, 100% écologique et adaptable sur tout type de véhicule, scooter ou tricycle, venez découvrir le froid du futur pour une livraison urbaine efficiente et durable.

Désengorger les centres-villes

Si ces dernières années, les métropoles ont globalement su rationaliser les flux de circulation des personnes, le transport des marchandises reste à optimiser.

La logistique du dernier kilomètre est la plus difficile à gérer :

Cela n’est pas sans poser de problèmes dans les centres-villes, déjà envahis par les camions de livraison et en proie aux engorgements, aux nuisances sonores, et à la pollution. Ce sont, in fine, les citadins les premiers impactés, dont la qualité de vie est en péril.

Repenser la livraison urbaine de demain

En 2050, on estime que 68% de la population mondiale vivra dans les métropoles, contre 55% aujourd’hui. L’impact sera considérable dans les grands centres urbains.

Face à ce constat et à l’ampleur des enjeux environnementaux, il est urgent de trouver des solutions écologiques pour désengorger les centres-villes, tout en répondant aux besoins de services attendus par les citadins.

Un système de réfrigération autonome écologique, adaptable à tout type de véhicule

Imaginiez-vous pouvoir un jour livrer des produits surgelés, frais ou chauds, sans risque, à toute heure du jour ou de la nuit, sans bruit et sans pollution ?

C’est ce que rend possible la technologie développée par l’entreprise Coldway Technologies : un système de production de froid complètement autonome et écologique, qui peut être adapté sur n’importe quel type de véhicule, scooter, tricycle ou vélo.

Cette technologie de réfrigération est unique :

Ce système frigorifique 100% autonome et 100% écologique apporte une solution innovante et unique pour faciliter les livraisons du dernier kilomètre en centre-ville, sans nuisances et sans pollution.

Venez la découvrir les 11 et 12 février au salon Move à Londres, le plus grand salon dédié à la mobilité urbaine.

En effet, en restant sur ce navigateur vous ne bénéficiez pas d'une expérience optimale. Vous risquez de rencontrer quelques problèmes d'affichage ainsi qu'une baisse de performance. Pour y remédier, vous pouvez utiliser un navigateur plus récent qu'Internet Explorer 11 tel que Google Chrome ou encore Mozilla Firefox.